How Is Whey Protein Made?

So you wanna know how whey protein is made, huh? Well, lucky for you, we’ve put together the easiest, most entertaining explanation that you’ll ever find on the internet! But don’t let that fool you, this article packs a punch and you’re gonna have to pay attention. So chop chop, student! Let’s get to it.

To start off,

Did you know that you could make protein powder at home too?

“WHAAT?, you’re saying that I could make this tub of liquid gold at home, and save a TON of bucks? Tell me, tell me more now!”

Well…both yes, AND no.

You can make it home. And I’m going to tell you exactly how to, but, about the saving money part….umm, we’ll get to that later.

Also, if you’re more of a video person, watching this will help you understand explains the at-home process.

The at-home method:

- To begin with, grab yourself a pot of milk.

- Bring that milk to a boil and then add some lemon juice or vinegar to it. At this point, you’ll see the milk start to separate into curds, which will float at the top, and a yellowish liquid.

Now, these curds you see, you can use them to make all kinds of cheese, or if you’re desi, ras malai! 😉

- But don’t just throw away the rest of the liquid. No, no, no! That, my friend, is liquid whey. And this is what you’re going to use to make whey protein powder! Pretty cool huh?

Now, this is the point of the recipe where things start to get a little complicated, (and expensive 😭)

- For the next part, you’re going to need something you probably don’t have: a food dehydrator.

The food dehydrator will suck out all the moisture in the liquid whey and turn it into a dry, crumbly, solid. When the dehydration process finishes, you’re left with something that looks like this…

Dump this into a food processor, and you’ll get the powder consistency that you’re looking for, and voila! There you have it. Homemade protein powder!

Now onto the big question:

“Can I use this as a replacement for commercial whey protein powders?”

Unfortunately, if you actually went forward with the homemade one, you’re going to run into two BIG problems.

Is it worth it?

- 500 liters of milk needed to make 1 kg of whey protein! So, unless you’ve got a big dairy farm at your disposal along with huge dehydrators, this probably isn’t the way for you.

- Low % of protein per gram. Let’s not forget that milk contains a bunch of other nutrients like fats, lactose, and carbs. And we haven’t done anything to filter them out, so they’re going to be present in our whey as well.

You’re bursting with anger, thinking:

“If making it at home isn’t worth it, then why’d you tell me all about it?!”

Don’t shout at me, I was only trying to help! 😭😭😭

But crying faces aside, because I told you of the homemade way first, you’ll understand the factory way much faster!

It’s the same principles, scaled up. Some heavy-duty machinery, and A LOT more milk!

Let’s start from the beginning.

The Factory Method:

Step 1: Milk.

You probably got yours from your local milk vendor or grocery store, but for the whey industry, the milk comes straight from a dairy farm.

Step 2: Pasteurization.

From the dairy farm, the milk is sent to a cheese-making facility.

To make the milk safe for human consumption, it is pasteurized. This means heating the milk to its boiling point (70-80 C) and then instantly cooling it down at 4C.

This sudden change in extreme temperatures doesn’t allow bacteria to survive, leaving it free from bacteria.

Step 3: Separation

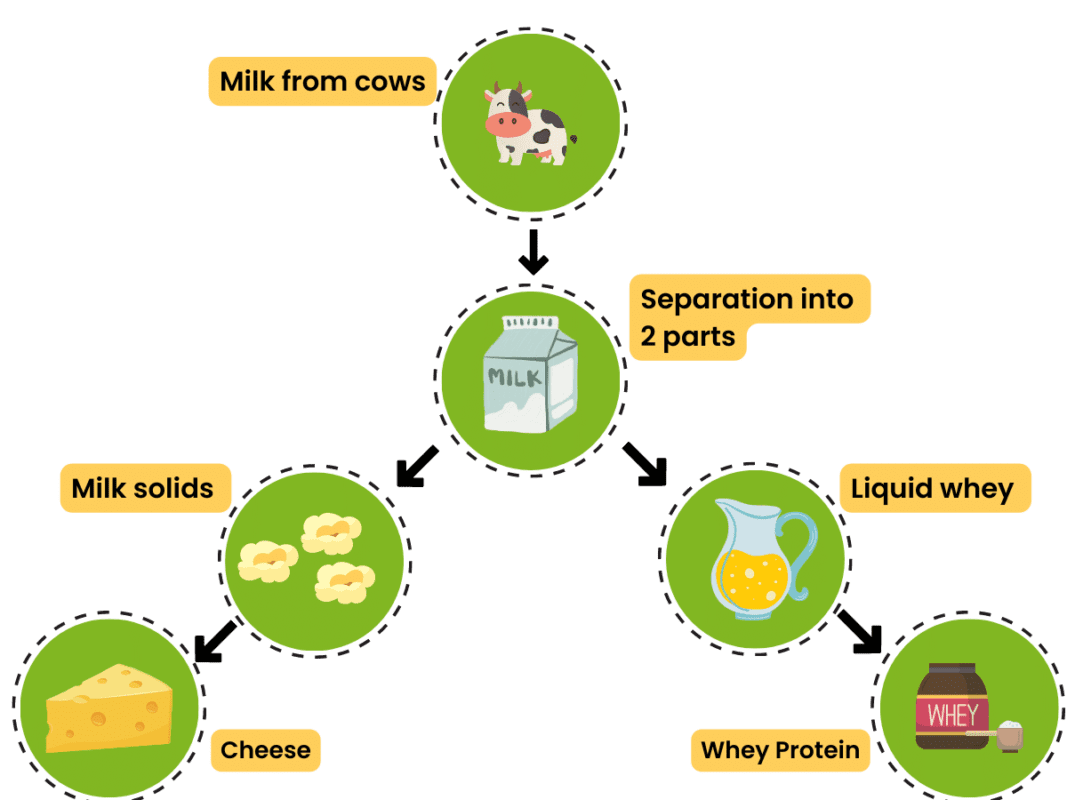

This is where the real action happens. Like how we added lemon juice to our milk in the at-home method, the pasteurized milk here is subjected to enzymes. And just like before, the milk will separate into two parts: liquid whey and casein.

Oh, I didn’t mention this before, but the curds that float on top are known as ‘casein’ solids. We’ve got another article all about casein, but the next time you see a tub of casein powder, at least you’ll know what it is!

The cheese factories use the casein, and send the liquid to a nearby whey production facility.

Step 4: Purification

For the at-home method, we dehydrate the whey liquid to get solid whey. But, this liquid contains a bunch of carbs, fats, and other minerals that aren’t ideal to have in your protein shake.

So, the liquid whey must be purified to remove fats, carbohydrates, water, and other minerals.

This is a rigorous process! And also where all the machinery comes into play, too.

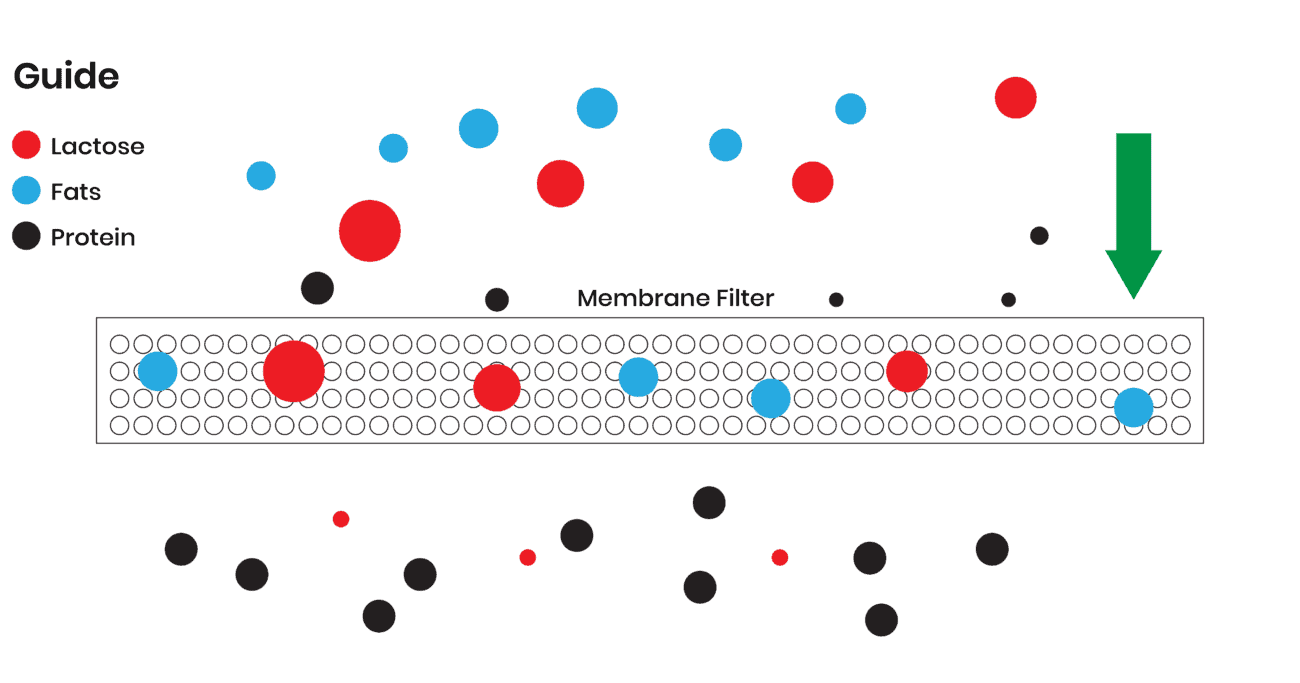

The liquid whey from Step 2 is collected and filtered to increase the concentration of protein and remove the impurities. The technology used here is membrane filtration. Simply put, the liquid whey is passed through a membrane (think of it as a very fine sieve)

The sieve allows the small components to pass through and retains the larger ones. This increases the concentration of protein in the liquid whey and removes impurities such as fats and minerals.

If you’re desi, then think of this process as passing your chai through a sieve (chalni). The sieve catches all the tea grounds, and you’re left with clean, refreshing, chai!

There are 3 levels of membrane filtration. Without going into too much boring detail about all of them, here’s a brief rundown of what goes on in each.

- Ultrafiltration: Removes most of the lactose of the liquid whey, leaves the proteins, plus also a tiny concentration of fats. The resulting liquid can have a maximum concentration of 80% protein. And this, my friends, is Whey Protein Concentrate (WPC) 80. The most commonly used spec of protein powder in the world!

- Microfiltration: This is ultrafiltration but in turbo! The sieve is finer, and the filtration is more rigorous. The fats are removed, and you’re left with a solution of up to 90% protein concentration. And this, dear readers, is Whey Protein Isolate (WPI) 90. One of the purest sources of protein out there.

- Nanofiltration: Superfine membrane with very tiny pores. Separates the protein from virtually everything.

Step 5: Drying

This brings us to the last part of the processing of the whey. We started with milk. Turned that into liquid whey, filtered it, and now we must make the switch into a powder.

At home, we used a dehydrator. In a factory, however, they use something called a spray dryer. It has hot as well as cold air that dries out all the water and separates the solids from the liquid.

And just like before, voila! Whey protein powder. The WP here is now ready to be flavored and packed. This is the end product and the one available for you to buy.

Here’s a little diagram that’ll make this a lot easier to understand and remember!

Step 6: (optional, but highly recommended 😉 )

You order from PakNaturals, and we ship you your kit of “Flavor yourself” WPC 80 onto your doorstep!